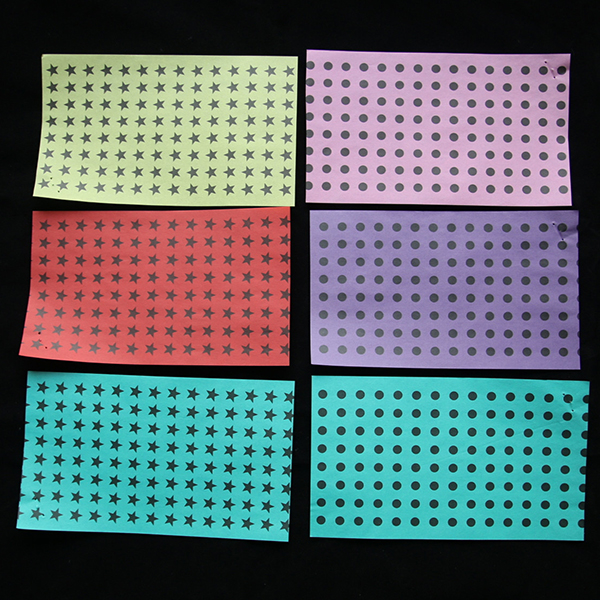

Product Details

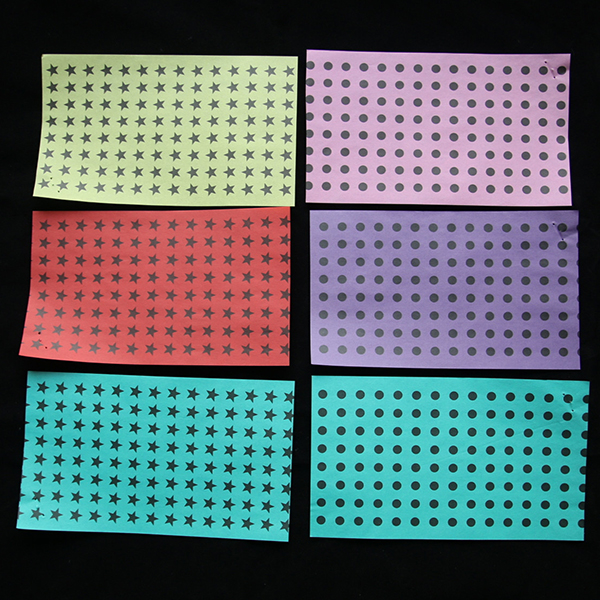

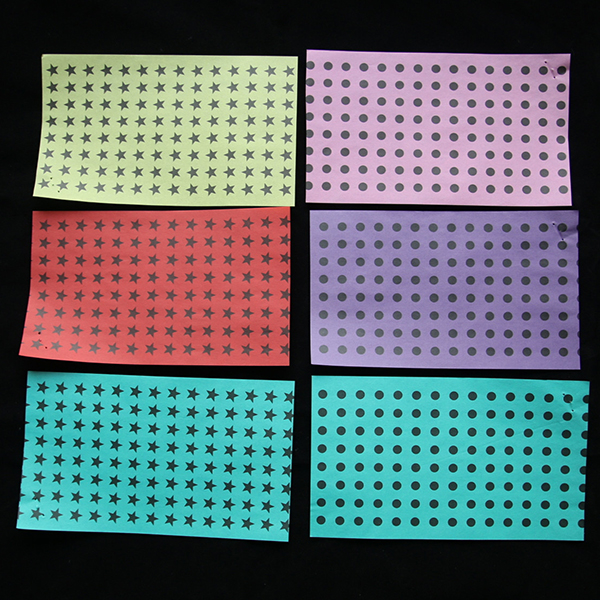

Printed parchment paper can print various patterns or logos according to customer requirements, with more vibrant colors and

better quality.

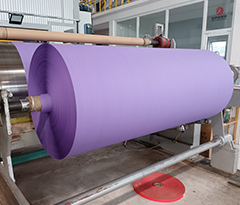

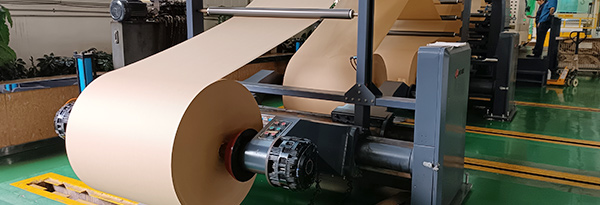

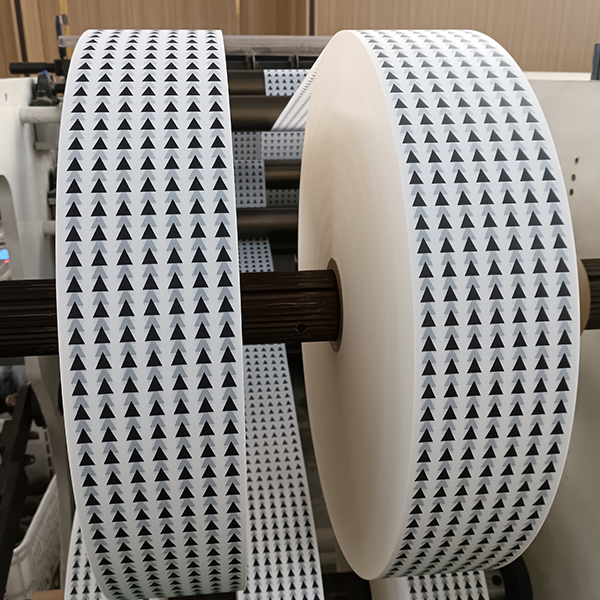

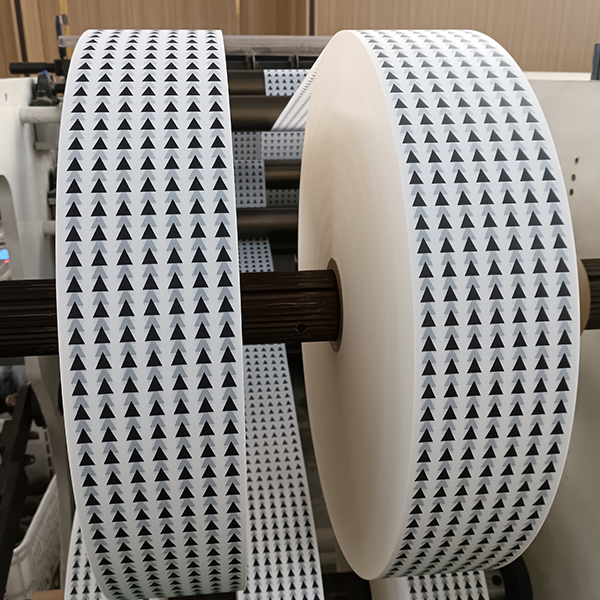

This product is semi transparent, has low breathability, low porosity, oil impermeability, and is not easy to burn; Parchment paper undergoes a series of parchmentizing processing to form various specifications of parchment paper, which can be printed with various patterns according to customer requirements. Our company currently has six advanced parchment production lines with an annual production capacity of 20000 tons. We can produce various specifications of printed parchment paper ranging from 40 g to 100g according to user requirements, and the product quality meets the advanced level of our peers.

Product features:

Standard:FDA、SGS、FSC、BRCGS、LFGB、QS

Weight:Standard 40 to 100 gsm

Features: No chemical additives, waterproof, greaseproof, and high-temperature resistant

Advantages: Smooth paper surface, with high uniformity, good transparency, and high strength.

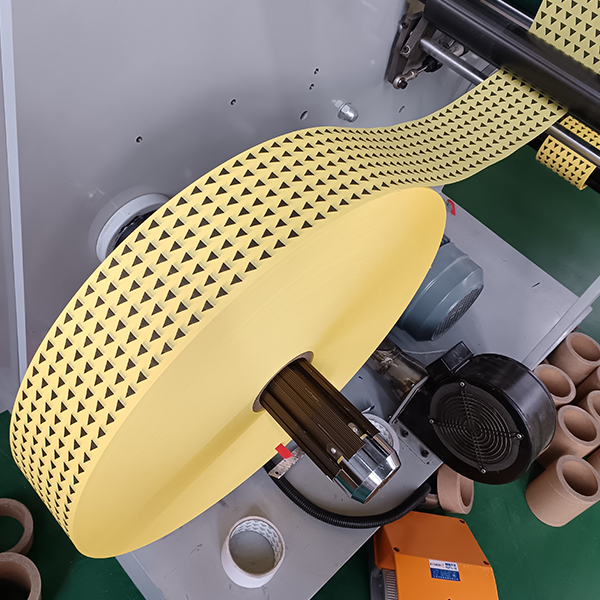

Specifications: It can be cut into various rolls and sheets.

Pattern: Template printing is made according to customer requirements, with good printability

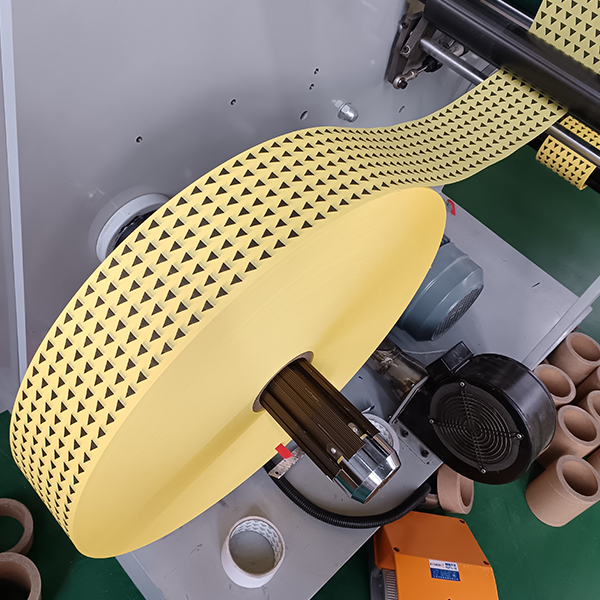

Product Usage: The printed parchment paper produced by our company is mainly used in the chemical fiber paper tube industry.

Its main function is to wrap around the outside of the paper tube. Due to the characteristics of oil and water resistance, smoothness, and no silk hanging of parchment paper, it can reduce the loss of raw silk and improve the yield rate. At the same time, it is widely used in industrial product packaging such as mechanical parts, instruments, and chemical drugs